Solution

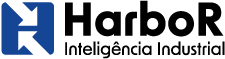

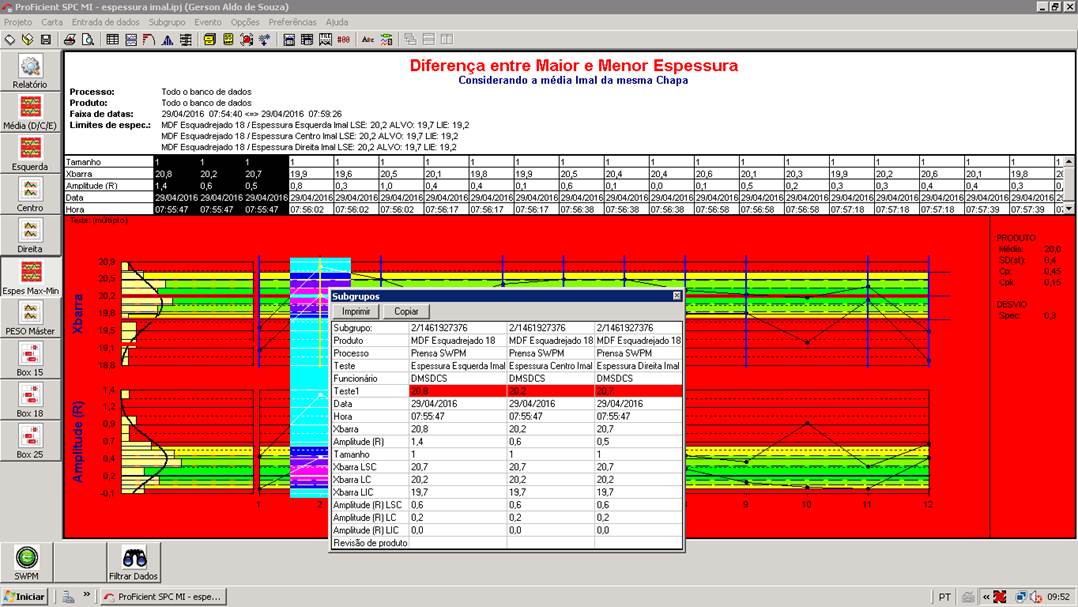

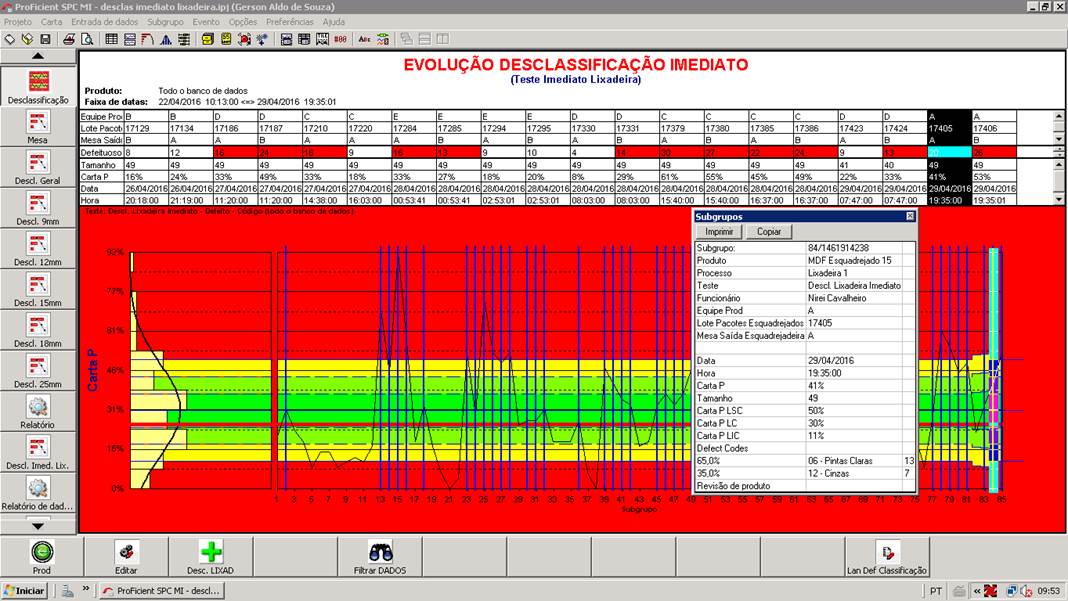

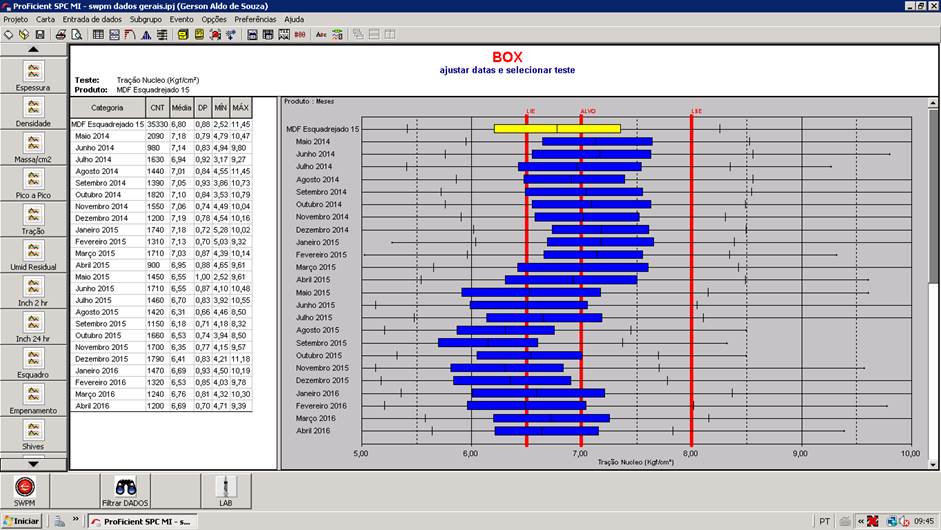

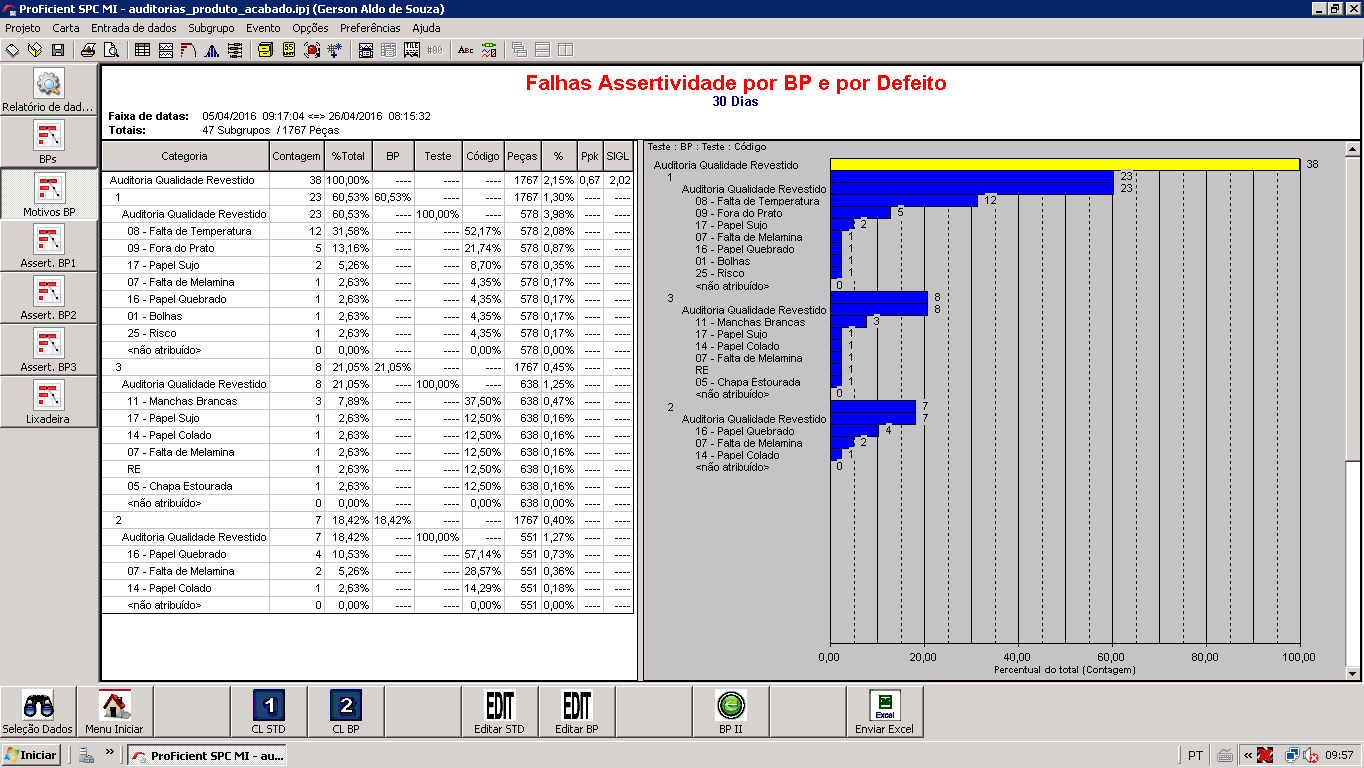

Guararapes relied on HarboR Informática Industrial to implement InfinityQS, a solution for intelligent manufacturing, quality control and Statistical Process Control. HarboR implemented the software completely at the Caçador factory. Automatic data collection was connected to InfinityQS via the industrial network. By automating the data, it was possible to relate production data in real time to the analyses carried out in the laboratories and on the shop floor, as well as to generate e-mails warning of non-conformities. Graphs and reports were set up to analyze the results of the production processes and make decisions.

Since the implementation of InfinityQS, HarboR has been providing support, maintenance and training services for the software and monitoring the use of the tool to drive continuous process improvement at Guararapes Caçador.

For more details on the implementation, see the Details section at the end of this document. There you will find more about the products

InfinityQS ProFicient SPC

,

DMS

e

RAMS

used in this solution.

“With access to all the variables of the Siemens PLCs, we can identify and recognize them through InfinityQS. We also have RAMS to complement this, which automatically generates emails for those responsible. An interesting example is that we put temperature gauges at the entrance to the coating presses. The maximum temperature indicated for coating the panels is 45ºC. Whenever this temperature is exceeded, alarms are generated and the shop floor staff change the raw materials for ones that are better acclimatized. In this way, they prevent the risk of streaks in the final product, reducing the chance of problematic material reaching the customer”

-Gerson Aldo de Souza, Technical Manager