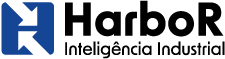

The RDE System uses the presence sensor to know how many parts have been produced at which station/operation on the line, so whenever a part passes in front of one of the sensors, the system knows from the sensor which station the part was produced at and counts it.

As it is not possible to take a PC to each operator’s workstation, we opted for a solution where defects are collected using a device called a 16-key microterminal with a 2-line display. This equipment is similar to bank terminals where the card and password are swiped, but it is designed for an industrial environment. We chose to use this equipment due to its ease of use, ease of replacement and low cost.

To use these terminals, a numerical coding scheme was designed, so for each fault there was a numerical code. With the 2-line display, messages can be sent to instruct the operator to do the correct procedure. Messages, for example, with a description of the fault (so that the operator can be sure that he is calculating the correct fault), product change messages, product model, etc….

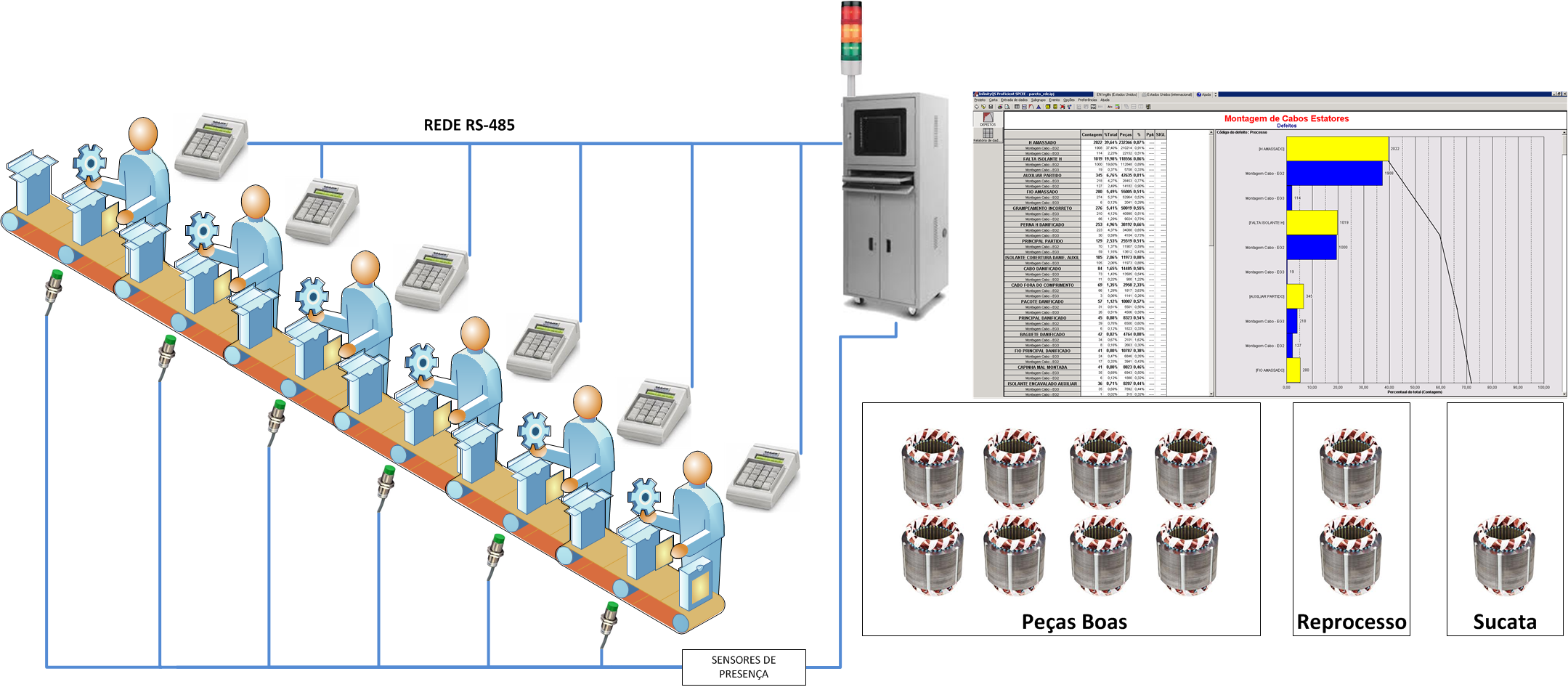

The RDE has the 2 pieces of information needed to make Attribute CEP, the quantity produced (detected by the presence sensors) and the number/type of defects that have occurred. This data is therefore sent directly to the InfinityQS database.

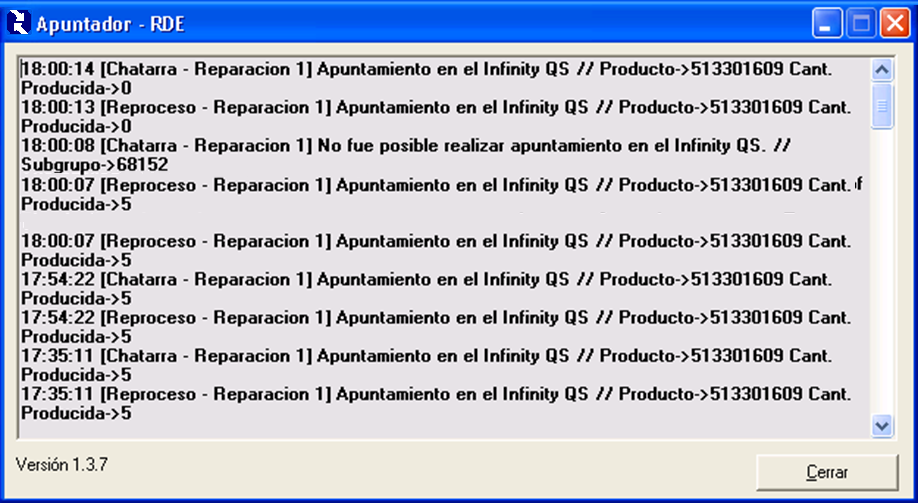

Once in the InfinityQS database, on any PC (with InfinityQS installed), all you have to do is open a project with Attribute ZIP Code charts and the statistical analysis is done when the chart is loaded. In the case of the company in question, we chose to visualize the data in Pareto Charts, but InfinityQS has more than 300 different types of charts for visualizing ZIP code information.

In addition to graph visualization, InfinityQS also generates alarms (based on pre-registered Specification Limits) and has Logbook support.

The solution enabled the company in question to reduce the occurrence of defects by 97% for both rework and scrapping, thus remaining well above the target value of 80%.

Benefits

- Increase in the quality of the products produced

- 97% reduction in cases of product reprocessing and scrapping

- Anticipating possible defects

- Significant improvements in the manufacturing process

- Greater operational efficiency

- Usability for computing defects at the operator’s own workstation

- Online monitoring by management of the occurrence of defects and the progress of the production process

- Low cost of the integrated solution

Features offered

- Product exchange via microterminal

- Defect collection via microterminal

- Automatic production counting

- Integration with the ZIP Code System

- Automatic Attribute CEP

- Making information available online

- More than 300 possibilities for analyzing attribute ZIP code information

- Alarms and alerts on the occurrence of defects, through alarms on graphs and sending e-mails

- Logbook to correlate defects with changes and situations found on the production line

System interfaces

* Images with fictitious data (illustrative only)