Solution

Exal Brasil chose to work with HarboR Informática Industrial to deploy InfinityQS, a smart manufacturing and quality control software featuring a powerful SPC tool. Initially running on one production line, HarboR configured InfinityQS to record checklists, quality and production data, enabling analysis and management of this information. The factory floor sampling requirements were structured to maintain controlled frequency via Dynamic Scheduler, prompting operators when to collect and requiring justification if violated. In parallel, laboratory technicians can view production records in real time and record their own analyses. HarboR was responsible for training key InfinityQS users, equipping them with core configurations, apps, and software functionalities.

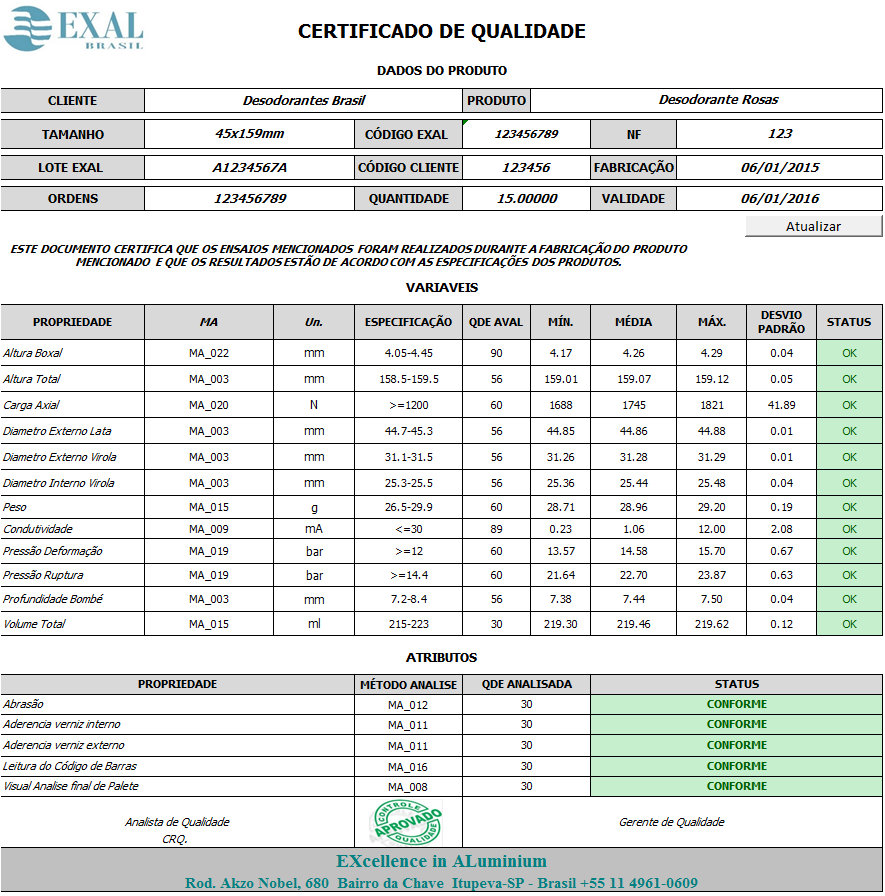

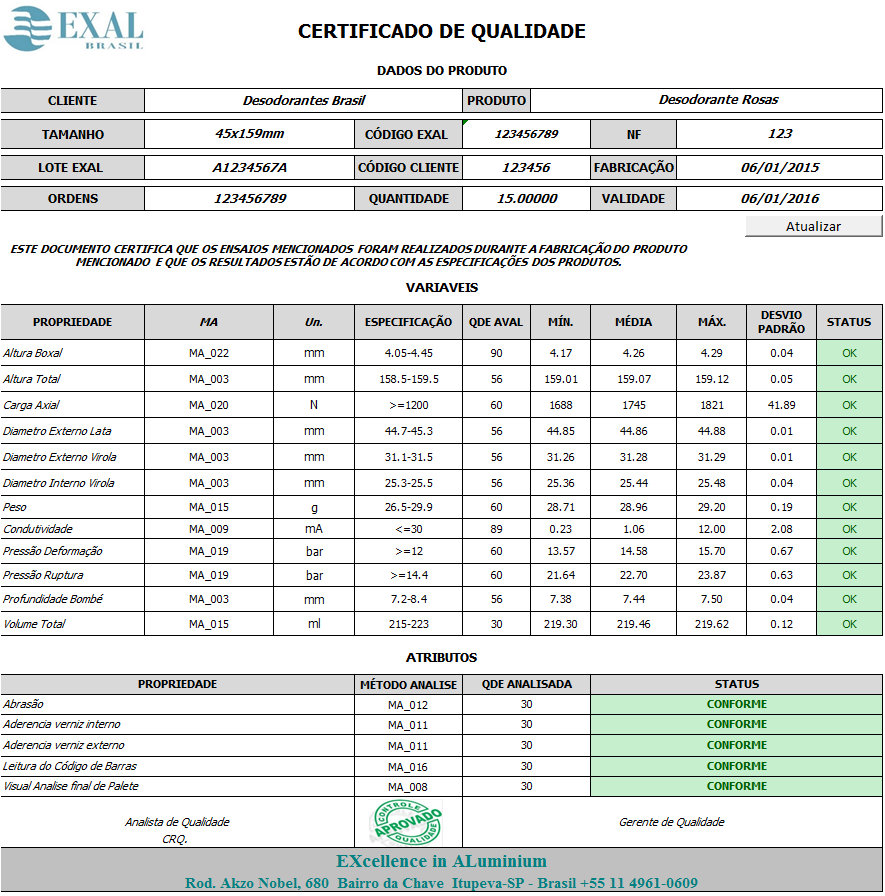

“InfinityQS helps us manage data and when we need to generate graphs for clients. The information is well-organized and easily accessible for analysis. Since we need to send certificates to clients, the quality certification system developed by HarboR has been very helpful, as it’s easy to use.”

-Juliana Brito, Analista de Processo e Qualidade

To automate quality certificate filling, HarboR developed a custom Excel spreadsheet integrated with the InfinityQS database. A lot search enables auto‑filling certificate fields with values stored in the database. An analysis status is generated by comparing collected values with engineering specifications.