C‑Pack Creative Packaging is a packaging company born from a Swiss‑Brazilian initiative that began plastic packaging production in 2002, aimed at providing innovative and differentiated packaging solutions through intelligent and sustainable application.

The company serves pharmaceutical, food, industrial, and cosmetic segments, with a strong focus on cosmetics, supplying plastic tubes and caps to leading players in Brazil and abroad. It currently operates a newly opened 36,000 m² facility in Santa Catarina with an annual capacity of 220 million tubes/year, employing around 400 people across three shifts, and holds SA8000 certification (since 2005) and ISO 9001.

The company’s innovative products feature the following advantages:

- Permanent diameter control

- Options for translucent or pigmented packaging

- Offset decoration up to 8 colors, with matte or glossy varnish

- Automatic silk-screen decoration up to 6 colors + matte or glossy varnish

- Hot stamping finish with camera-based positioning

Main goals of SPC implementation

- Reduce the number of items segregated per batch produced

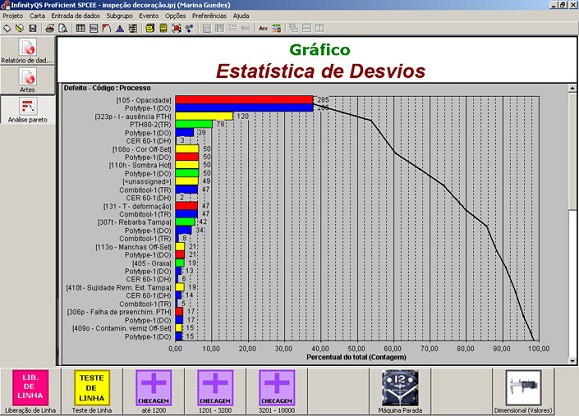

- Monitor the processes that cause key product defects (per process: machine + operator + setup + raw material)

- Control occurrences of major product defects

- Monitor processes to ensure dimensional conformity, especially tube and cap diameters

- Monitor online quality to be more effective in driving improvements

Secondary objectives

- Have fast access to historical quality management information

- Control access to historical quality management data

- Maintain quality management data in an computerized system protected against loss

Previous situation

C-Pack already had a product quality control system based on sampling analysis where defect and dimensional data was analyzed on all the products in the sample. The acceptable limits for defects and dimensions in the sample vary depending on the batch size and when these limits were violated in a sample, the entire batch was segregated, thus ensuring that products would not be sent to the customer outside the pre-agreed limits.

All the information was collected by inspectors on standard note sheets, which were then compiled and stored in large binders that occupied a room in the company’s old headquarters.

In this structure, the quality situation in the company was:

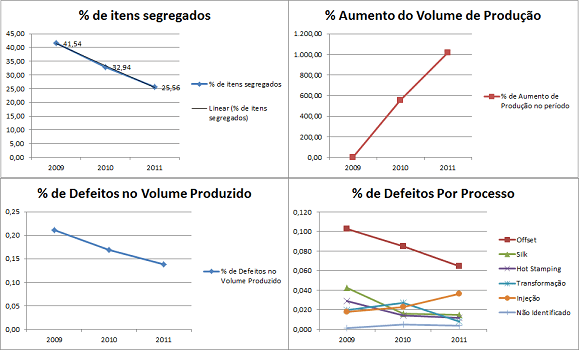

- Over 40 % of items segregated per batch

- Just over 0.20 % defects in production volume

- Long delays (days) to search and compile historical data

- Long delay (hours) between defect occurrence and detection

Proposed solution

At the end of 2008, HarboR implemented the complete InfinityQS SPC (Statistical Process Control) solution, making the most of the existing and institutionalized mechanism for inspections and acceptable limits per product/batch. In addition to computerizing this input information, the concepts and benefits of SPC analysis were also added, made available by the more than 300 types of InfinityQS analysis charts.

The complete solution includes:

- Situation analysis and implementation plan

- Supply of the InfinityQS SPC solution

- In-company training for the entire quality team in CEP and the InfinityQS system

- Implementation and configuration of the InfinityQS CEP system

- Development of EBC data collection projects (replacement of forms)

- Generation of EBC control charts for attributes (defects and defective)

- Generation of variable (dimensional) SPC control charts

- Optimization of projects taking into account usability features, agility, human error proofing

- C-Pack server configuration to protect the system and especially the data from possible failures or errors

- Monitoring the start-up of the system and the analyses generated by it

- Integration of the CEP system with the existing Business Intelligence system, providing a universe for analyzing consolidated quality data

- Full post-implementation support for questions, improvements in the way you use and software upgrades

Results

The period analyzed covered the whole of 2009, 2010 and 2011, so 3 years. During this period, C-Pack increased its production volume by more than 1000% with the inauguration of the new plant and the acquisition of new production lines. Even with such an increase in production volume over these 3 years, the following results were obtained:

- 39 % reduction in segregated items

- 34 % reduction in defects

- Direct reduction of losses in the order of R$ 15,342,788.64

- Reduced time spent searching for historical information

Benefits

In addition to the results already mentioned, the following benefits were obtained:

- Real-time monitoring of production processes and consequently a reduction in segregated products and an increase in product quality

- Using statistical information from the CEP to improve the production process

- Identification of the main causes of defects by process and by product through graphical analysis and logbook monitoring

- Instant and active activation of alarms generated in the event of a limit violation and immediate warning to those responsible

- Increased guarantee of dimensions within the specifications for tubes and caps

- Decreased decision-making time

- Reduced time to correct processes, thus increasing production efficiency and helping to reduce complete batch losses

- Reduced production costs

- Increased warranty against replacement and customer-identified problems (recalls)

- Increased operational efficiency

Final Considerations

It should be emphasized that the results obtained are mainly the result of a joint effort by C-Pack’s quality team, which is constantly striving to improve quality, together with HarboR, which played an active role in this process, providing a solution tailored to the needs of the quality sector. This solution was put together taking into account the company’s culture (what was already in place and institutionalized), assessing present and projected risks and needs, and providing human and technological capital and all the pre- and post-implementation support so that the quality improvement plan at C-Pack could take place and be maintained.